For a perfect bumper paint touch-up, use OEM-approved products as they are specifically designed and tested by car manufacturers for exact color matches, durability, and structural integrity. These products consider unique frame characteristics, ensuring seamless integration and maintaining the car's safety and aesthetic appeal. Adhering to best practices, including thorough surface preparation, primer application, even coats of high-quality paint, proper ventilation, and a clear coat finish, guarantees a flawless bumper touch-up using OEM materials, enhancing durability and long-term cost savings.

Bumper paint touch-up is a crucial aspect of automotive maintenance, ensuring your vehicle’s aesthetic appeal and protecting its value. In this article, we explore the significance of using Original Equipment Manufacturer (OEM)-approved products for bumper repairs.

Learn about the benefits of OEM parts, from precise color matching to superior durability. We provide best practices to guarantee effective bumper paint touch-up, offering step-by-step guidance for professionals and DIY enthusiasts alike. Discover why this approach is essential for achieving a flawless finish and maintaining your car’s overall quality.

- Understanding OEM-Approved Products for Bumper Paint Touch-up

- Benefits of Using Original Equipment Manufacturer (OEM) Products

- Best Practices for Effective Bumper Paint Touch-up with OEM-Approved Materials

Understanding OEM-Approved Products for Bumper Paint Touch-up

When it comes to bumper paint touch-up, using OEM-Approved products is paramount for achieving a flawless finish that matches the vehicle’s original specifications. These products are specifically designed and tested by Original Equipment Manufacturers (OEMs) to ensure they align perfectly with the car’s make and model. By utilizing OEM-approved materials, bumper touch-up technicians can guarantee color accuracy, durability, and long-lasting performance.

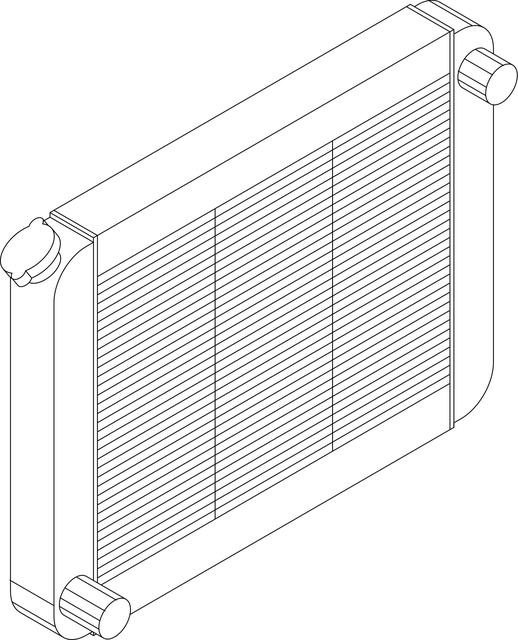

Choosing the right products is crucial in a vehicle body shop, especially when dealing with intricate auto painting tasks like bumper repairs. Unlike general aftermarket paints, OEM products consider the unique frame straightening and structural integrity of each vehicle, ensuring a seamless integration during the touch-up process. This level of precision not only maintains the aesthetic appeal but also preserves the overall safety and reliability of the vehicle.

Benefits of Using Original Equipment Manufacturer (OEM) Products

Using Original Equipment Manufacturer (OEM) products for bumper paint touch-up offers a multitude of advantages that set it apart from generic alternatives. First and foremost, OEM products are designed to match the exact specifications and quality standards of the vehicle manufacturer. This ensures not only an impeccably smooth finish but also perfect color harmony with the rest of the car’s exterior. By employing these approved products, bumper paint touch-up technicians can deliver a flawless repair that is virtually indistinguishable from the original manufacturing work.

Moreover, relying on OEM parts for collision repair services and auto body repair enhances durability and longevity. These products are crafted using high-quality materials and state-of-the-art manufacturing processes, ensuring they withstand the test of time and environmental conditions. This not only guarantees a more robust repair but also reduces the need for future touch-ups, making it an economical choice in the long run for both technicians and vehicle owners alike.

Best Practices for Effective Bumper Paint Touch-up with OEM-Approved Materials

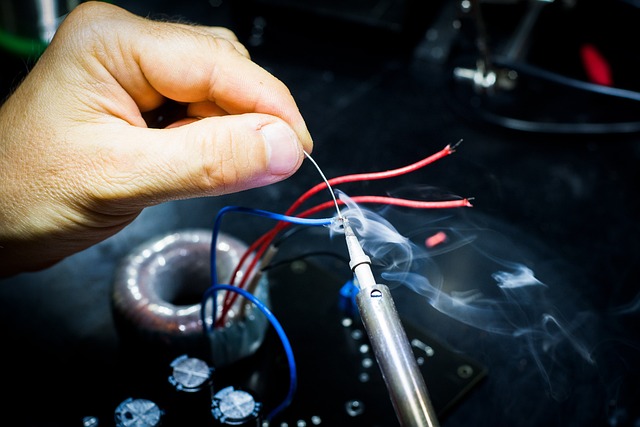

When performing bumper paint touch-up with OEM (Original Equipment Manufacturer)-approved products, adherence to best practices is paramount for achieving a flawless finish that matches the vehicle’s original specifications. Begin by preparing the surface thoroughly; this involves sanding down the damaged area to ensure proper adhesion of the new paint. Remove all dust and debris using a clean cloth or compressed air to create a smooth base.

Next, carefully apply the OEM-approved primer, allowing it to dry evenly. This step is crucial as it promotes better paint bonding. Use high-quality bumper paint designed for durability and color accuracy, matching the vehicle’s exact shade. Apply thin, even coats, letting each layer cure as recommended by the manufacturer. Ensure proper ventilation during the painting process and always follow safety guidelines for handling chemicals. Completing the touch-up with a final clear coat adds protection and ensures the new paint lasts, maintaining the vehicle’s aesthetic appeal through professional-grade body shop services.

When performing a bumper paint touch-up, using OEM-approved products is paramount for achieving a factory-like finish. These specialized materials ensure compatibility and quality, enhancing the overall aesthetics of your vehicle. By adhering to best practices and understanding the benefits outlined in this guide, you can confidently restore your bumper to its former condition, maintaining both the value and appearance of your vehicle.